Outrageous Cold Form Blister Packaging

Shop our selection of packaging products.

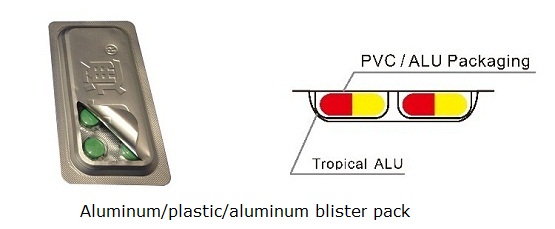

Cold form blister packaging. The special polyester film is all set to replace the top and bottom substrates of the conventional cold formed Alu Alu laminate to a whole new structure comprising 36 micron special polyester 50 micron soft aluminum foil 36 micron special polyester. It is also estimated that the demand for cold form blister packaging will grow at a good CAGR value for the Food Confectionary and Other Industrial Application. The primary component of a blister pack is a cavity or pocket made from a formable film usually a thermoformed plastic or cold formed aluminum film.

It is used by pharmaceutical industry for packaging a many products including tablets capsules drugs vials ampoules syringes or liquid products. Cold form blister packaging comes from sandwiching aluminium foil between polyvinyl chloride PVC and nylon films using dry bond lamination technology ALNYPVC. FDA registered facility certified to iso22000 13485 9001 FFSC22000 compliant.

The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate. Ad Need high quality packaging for food beverage. UFlex Alu Alu packging is a next big thing in pharma packaging.

Furthermore oppor-tunities for product contamination are minimal and each dose is identified by product name lot number and expira-tion date. The combination of materials used for blister packaging film give the Cold form foil film the critical properties needed to produce blister packaging that protects the. Alu Alu foil is an excellent multilayered structure designed for highly sensitive range of pharmaceutical and generic medicines which are highly hygroscopic or light sensitive and cannot be suitably packed with barrier plastic films.

Formpack New Generation Cold Form PVC-free Pharmaceutical Blister Pack Invented by Amcor Flexibles former Alcan Packaging the Formpack blister alualu provides the highest possible product protection against moisture oxygen and light for individual doses of pharmaceutical products medical devices and diagnostics. Alu Alu Foil Aluminium Cold Forming Blister Foil. It is hundred percent barriers to moisture air and gases.

The cold form blister packaging is also used for the packaging of various veterinary products and inhalants. Cold form blister packaging displays enhanced delamination resistance as well as offers optimal protection to extend shelf-life of products. The packaging provides an effective barrier to light moisture gases and oxygen to keep the product intact.